How Coconut Brick Manufacturers Are Shaping the Future of Farming

A sustainable shift is reshaping modern agriculture, with coconut brick manufacturers emerging as key innovators in advancing eco-friendly cultivation practices. Coconut bricks, also known as cocopeat bricks, are compact blocks made from coconut husk fibers that are redefining farming, gardening, and hydroponics practices. By replacing traditional soil amendments with these eco-friendly bricks, growers around the world are improving soil health, conserving water, and embracing more sustainable agriculture. In this article, we explore what coconut bricks are, their benefits, how manufacturers ensure top quality (through measures like low EC and proper drying), and why Tamil Nadu has emerged as a leader in this industry. We also highlight how Greglo, a leading player from Tamil Nadu, exemplifies quality and sustainability in coconut husk products.

What Are Coconut Bricks (Cocopeat Bricks)?

Coconut bricks are compressed blocks of coir pith (coco peat) derived from coconut husks, a by-product of the coconut industry. After coconuts are harvested for food or fiber, the remaining husk is processed to extract coir fibers, leaving behind a spongy material called coir pith or coco peat. Manufacturers wash, dry, and compress this coconut coir peat into brick or block form for easy handling and transport. Once water is added, the compact brick expands significantly (a 5kg brick can yield many times its volume in moist growing medium) to create a light, porous growing substrate. These coconut bricks serve as a soil-less medium or soil conditioner that is clean, organic, and ready to support plant growth. They are popular among horticulturists as a sustainable alternative to traditional peat moss, as coco peat can hold large quantities of water like a sponge and is free of the environmental damage associated with peat mining. In essence, cocopeat bricks provide an easy way to ship and use coconut coir for agriculture—just add water and they transform into a nutrient-friendly, root-friendly growing medium.

Benefits of Coconut Bricks for Farming, Gardening, and Hydroponics

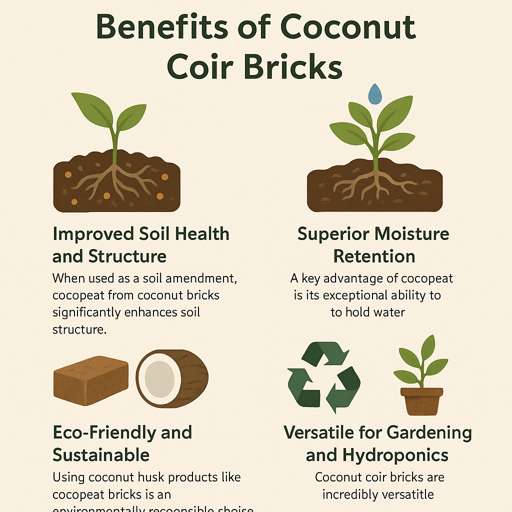

Coconut coir bricks have numerous advantages that are transforming modern farming techniques, home gardening, and hydroponic systems. Below are some of the key benefits that make cocopeat bricks a game-changer in agriculture:

- Improved Soil Health and Structure: When used as a soil amendment, cocopeat from coconut bricks significantly enhances soil structure. The coir fibers create air pockets in the soil, improving aeration and promoting healthy root development. This loosens compacted soils and helps roots spread more easily. Additionally, coir is slow to decompose, so it improves soil organic content over time without breaking down rapidly. Gardeners and farmers find that mixing cocopeat into soil leads to better root zone oxygenation and overall plant vigor.

- Superior Moisture Retention: A key advantage of cocopeat is its exceptional ability to hold water. Coconut coir can absorb and retain moisture many times its weight, helping plants maintain steady hydration and reducing the frequency of watering.For farmers in arid regions or gardeners who want to reduce watering frequency, cocopeat bricks provide a buffer against drought stress. In hydroponics and container gardening, hydrated cocopeat releases water slowly to plant roots, maintaining an even moisture level. This superior water retention not only conserves water but also means plants experience less shock from drying out.

- Eco-Friendly and Sustainable: Using coconut husk products like cocopeat bricks is an environmentally responsible choice. Unlike peat moss (which is mined from fragile bog ecosystems), cocopeat is a renewable resource – it’s made from coconut husk waste that is abundantly available and would otherwise often be discarded. Cocopeat is sustainably produced as a byproduct of the coconut industry, and it avoids the ecological damage of peat extraction. Moreover, cocopeat is biodegradable and compostable after use, making it a circular product in horticulture. It is also naturally free of most soil-borne pathogens and weed seeds, since the coir is typically heat-treated and comes from inside coconut husks. This means cleaner, disease-resistant growing conditions for plants.

- Versatile for Gardening and Hydroponics: Coconut coir bricks are incredibly versatile. For traditional farming and gardening, they can be mixed into garden beds or potting mix to improve texture and moisture retention. In greenhouse horticulture and hydroponic systems, cocopeat bricks serve as a soilless growing medium – plants can be grown directly in rehydrated cocopeat, which acts as an inert substrate to anchor roots and hold nutrients. Coir’s near-neutral pH (usually around 5.5–6.5) suits many crops, and it can be combined with other amendments like perlite or fertilizers to tailor the growing mix. Whether cultivating vegetables, flowers, or high-value hydroponic crops, growers appreciate that cocopeat bricks are easy to transport, store, and use on demand by simply adding water. Additionally, coir can often be reused for multiple growing cycles (up to three times) with minimal loss of performance, making it cost-effective.

By providing a growing medium that improves soil quality, conserves water, and supports sustainable practices, coconut bricks are indeed transforming agricultural methods. Farmers and gardeners are increasingly adopting cocopeat bricks to boost crop yields and reduce their ecological footprint.

Ensuring Quality: How Manufacturers Maintain High Standards

Benefits for horses

Not all cocopeat bricks are created equal. Reputable coconut brick manufacturers invest considerable effort to ensure their product is of high quality, consistent, and suitable for sensitive plants. However, this is not without challenges. coconut brick manufacturers often face challenges and issues such as inconsistent raw material quality, high labor costs, seasonal availability of coconut husks, and the need to meet strict international standards for export. Despite these hurdles, here are some of the ways manufacturers maintain top-notch quality in cocopeat bricks:

- Low Electrical Conductivity (Low EC): Quality manufacturers make sure their cocopeat bricks have low electrical conductivity, indicating low salt content. Raw coir pith can contain natural salts (especially if coconuts were grown near coastal areas), which can hinder plant growth. To achieve low EC, cocopeat is thoroughly washed during processing to leach out these salts. By monitoring the EC levels of the coir (often aiming for a very low reading, suitable for even delicate hydroponic crops), manufacturers ensure the end product will not introduce excess sodium or potassium that could harm plants. Low-EC cocopeat bricks give farmers and growers peace of mind that the growing medium won’t contribute to nutrient imbalance or “burn” the plants.

- Proper Drying and Moisture Control: Controlling moisture content in cocopeat bricks is crucial for both quality and shelf life. Manufacturers dry the coir pith to an optimal level (often around 10–15% moisture) before compressing it into bricks.Thorough drying—whether through natural sunlight or mechanical dryers—helps prevent microbial contamination and keeps the cocopeat bricks lightweight, making them easier and more cost-effective to transport.. By keeping moisture in check (typically cocopeat bricks are specified at about 15% moisture), producers make sure the bricks will expand to the correct volume when rehydrated by the customer. Consistent moisture control also means each brick performs uniformly, which is important for commercial growers who rely on predictable expansion and water content in their growing media.

- Refining Through Screening and Grading: Prior to compression, the coir is carefully sifted and sorted to eliminate coarse fibers and unwanted particles, ensuring a cleaner, more uniform final product. Quality-focused cocopeat manufacturers sift the coir to achieve a consistent particle size. This ensures that the end-user receives a homogeneous product that hydrates evenly and has the desired texture (fine or coarse) for their application. Grading also involves removing any residual foreign matter. The result is a clean, uniform cocopeat brick that meets the expectations of professional growers.

- Compliance with International Standards: Leading cocopeat brick producers adhere to international quality standards and export regulations. This includes meeting phytosanitary requirements (ensuring the product is pest- and disease-free) and sometimes obtaining certifications for organic use or quality management (such as ISO certifications or RHP standard in horticulture). By following globally recognized standards, manufacturers in India (especially established cocopeat exporters in Tamil Nadu) demonstrate reliability and build trust with overseas clients. From consistent block weight and size, to proper labeling and packaging, every step is checked for quality. Many exporters also implement strict quality control procedures – testing batches for pH, EC, compression ratio, and expansion volume – to guarantee that buyers receive a premium product ready for immediate use in farms or greenhouses worldwide.

Through these rigorous measures – washing for low EC, controlled drying, careful grading, and standards compliance – coconut brick manufacturers ensure their cocopeat bricks deliver maximum performance. This commitment to quality is key to cocopeat’s success as a growing medium in modern agriculture, as it assures farmers that they can count on consistent results from each brick.

Tamil Nadu – A Hub of High-Quality Coconut Brick Manufacturing

When it comes to cocopeat and coconut coir products, Tamil Nadu stands out as a global hub of quality and innovation. This state in southern India has long been at the forefront of coconut cultivation and coir processing, providing an ideal environment for a thriving coconut bricks industry. Tamil Nadu’s leadership in coconut brick manufacturing is driven by several factors:

- Rich in Coconut Resources: As a leading coconut-growing state in India, Tamil Nadu benefits from a consistent and ample availability of coconut husks, forming a strong foundation for its thriving coir production industry. Regions like Pollachi and Coimbatore are dotted with coconut farms and processing units, creating an efficient supply chain for cocopeat producers. The availability of quality coconut husk means manufacturers can consistently produce coconut husk products like cocopeat bricks in large volumes to meet global demand.

- Established Industry and Expertise: The state has a rich tradition of coir product manufacturing, supported by skilled labor and entrepreneurship in the coir sector. Over decades, coconut bricks manufacturers in Tamil Nadu have honed their processes and knowledge, becoming specialists in turning husk fiber into premium growing media. This expertise translates into better product quality – Tamil Nadu’s cocopeat bricks are known for being well-processed (thoroughly washed, correctly dried, and properly compressed), which international buyers recognize and trust.

- Quality Reputation and Export Success: Tamil Nadu’s coconut brick manufacturers enjoy a strong reputation for quality on the international market. Many cocopeat exporters in Tamil Nadu adhere to stringent quality controls as discussed, ensuring their cocopeat blocks meet or exceed the expectations of growers in Europe, North America, Asia, and other regions. Buyers often seek out cocopeat from Tamil Nadu because they associate it with reliable expansion rate, low EC, and freedom from contaminants. The state’s infrastructure – including major ports like Chennai and Tuticorin – also facilitates smooth export of coir products worldwide, reinforcing its status as an export leader. In fact, India (with Tamil Nadu as a key contributor) is among the world’s largest producers and exporters of coir peat and related productsen.wikipedia.org.

- Innovation and Sustainability: The industry in Tamil Nadu continues to evolve with modern techniques. Manufacturers are innovating by offering various product forms (5kg blocks, 650g briquettes, coco discs, grow bags, etc.) to suit different horticultural needs. There is also a strong emphasis on sustainable practices – utilizing solar energy for drying, recycling water in the washing process, and ensuring that even the by-products of cocopeat production are used (for example, coir fibers for ropes or mats, and fine particles for compost). This progressive approach keeps Tamil Nadu at the cutting edge of the coconut coir industry.

Through these strengths, Tamil Nadu has rightfully earned its place as a leader in coconut brick manufacturing. International buyers looking for high-grade cocopeat often turn to Tamil Nadu’s cocopeat exporters for their proven reliability and quality-driven production.

Greglo – Leading the Industry with Quality and Sustainability

One prominent example of Tamil Nadu’s excellence in this field is Greglo, a Coimbatore-based company that has become a leading coconut bricks manufacturer and cocopeat exporter from India. Greglo has built its reputation by combining quality, sustainability, and outstanding service to meet the needs of both domestic and international buyers.

Founded in 2014 by visionary entrepreneurs, Greglo is proud to be one of Tamil Nadu’s top cocopeat manufacturersexportersindia.com. The company specializes in high-quality coconut husk products – primarily cocopeat blocks and related coir products – designed to support sustainable agriculture worldwide. Greglo’s commitment to quality is evident in its rigorous production process: only premium-grade coconut coir is selected, thoroughly washed to achieve low EC, dried to the optimal moisture level, and compressed into bricks under strict quality control. Each batch is tested to ensure it meets international standards for horticultural use. This focus on excellence has made Greglo a trusted supplier to growers who demand consistent, ready-to-use cocopeat bricks for their operations.

Sustainability is at the core of Greglo’s mission. By transforming coconut husk waste into valuable growing media, the company actively promotes eco-friendly, soilless agriculture. Greglo not only provides organic, biodegradable products, but also follows ethical manufacturing practices. As noted in their company mission, Greglo aims “to transform modern agriculture with eco-friendly, cutting-edge solutions”. This ethos is reflected in initiatives like using renewable energy where possible and ensuring minimal waste in production. Clients of Greglo appreciate that their purchases support an environmentally conscious supply chain.

Moreover, Greglo excels in international service and customer support. Based in the industrial hub of Coimbatore, Greglo leverages efficient logistics to ship products to clients across the globe in a timely manner. The company complies with international export regulations and customizes packaging and product specifications as needed for different countries. With a professional team, they provide attentive service — from prompt communication and documentation for export orders, to guidance on using cocopeat bricks effectively. This customer-centric approach has helped Greglo nurture strong partnerships worldwide, making them not just a supplier, but a reliable partner in their customers’ growth.

In summary, Greglo embodies the best qualities of Tamil Nadu’s cocopeat industry: premium product quality, sustainable innovation, and world-class service. For any business seeking a dependable cocopeat exporter in Tamil Nadu, Greglo stands out as a company that delivers coconut coir products with integrity and excellence.

Final Thoughts

Coconut brick manufacturers are indeed transforming modern agriculture by providing a sustainable, efficient growing medium that benefits both plants and the planet. From enhancing soil health and water retention to enabling soilless farming, cocopeat bricks have proven to be a versatile tool for farmers, gardeners, and hydroponic growers alike. When comparing cocopeat brick vs peat moss, cocopeat offers a renewable, eco-friendly alternative that does not deplete natural wetlands, making it the preferred choice for sustainability-conscious growers. Behind these advantages is the dedication of quality-focused manufacturers — particularly in Tamil Nadu, India’s hub for cocopeat production — who ensure that each brick meets high standards of purity and performance. Companies like Greglo exemplify how a commitment to quality, sustainability, and customer service can elevate a local coconut husk product to an international agricultural solution.

As agriculture continues to innovate towards eco-friendly practices, cocopeat bricks will play an increasingly important role in growing the food and plants we need, with less environmental impact. If you’re looking to experience the benefits of cocopeat bricks for your own agricultural or gardening needs, consider reaching out to Greglo. With its expertise as a leading manufacturer and exporter of coconut coir products, Greglo can provide the high-quality cocopeat solutions you need to cultivate success. (Contact Greglo today to learn more about how their coconut bricks can support your farming and gardening goals.)